Call for a free quote

+971 50 100 3699

Aluminum coil / Flat-rolled products

top Aluminum suppliers in the uae

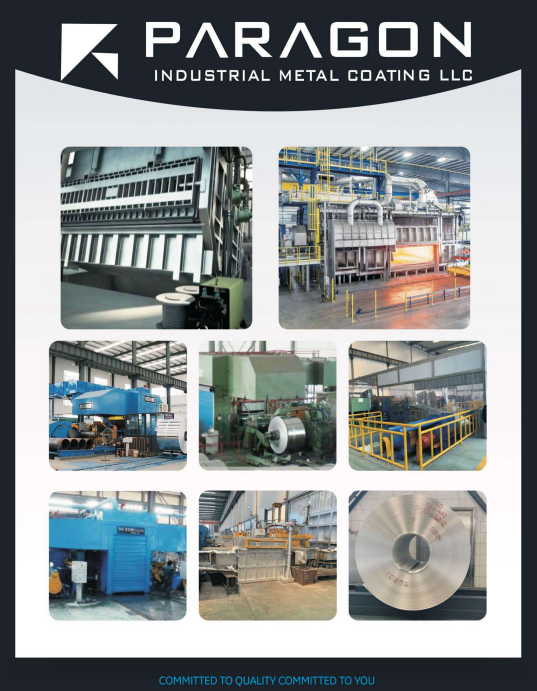

Paragon is synonymous with quality in the world of flat-rolled mill-finished aluminium coils and sheets. WIth our own manufacturing facility in India and an extensive factory in the UAE, we offer you the best range as well as most cost-effective solutions in the shortest time possible.

Alloy 3003/3004

aluminium with perfect flexibility

An aluminium alloy produced by mixing commercially pure aluminium with manganese, both 3003 and 3004 provide good corrosion resistance, workability and strength. Manganese is the major alloying element of 3xxx series alloys. These alloys generally are non-heat-treatable but have about 20% more strength than the 1xxx series alloys. They can be rolled, spun, bent, spun, drawn or welded based on the need. Both of these work more efficiently at higher temperatures compared to other aluminium alloys.

Alloy 3003 is widely used as a general-purpose alloy for moderate-strength applications requiring good workability. It has good finish, excellent formability, welds well, has moderate strength, and resists corrosion. Being the most versatile of all alloys, Alloy 3003 finds a wide range of uses, from N-95 masks to naval ships, aircraft and automobiles. Highly malleable with high plasticity, Alloy 3003 exhibits excellent rust-proof properties and is used in construction for roofing, siding and garage doors, as truck and trailer roofing in automobiles, and for pipe jacketing, gas lines and fuel tanks in the Oil and Gas industry.

Alloy 3004 has good corrosion resistance, workability and possesses more strength than alloy 3003. The most common usage of alloy 3004 is in its rolled form. Because it has 1% additional magnesium, it has the upper hand in strength compared to alloy 3003. One can find Alloy 3004 most commonly used in beverage cans (replacing alloy 3003 owing to thinner cans being produced) as it provides strength with malleability at thinner dimensions. It is also used in cooking vessels, chemical equipment, hardware, cabinets, storage tanks and lamp bases. Alloy 3004 is good for cold working, which is the only means of producing harder tempers of this metal.

alloy 3003/3004 features:

- Excellent corrossion resistance

- High formability

- Good workability strength

- Very good finish

- Welds well

- Multi-purpose usability

where is alloy 3003 most commonly used?

Alloy 3003 is used in numerous industries. In construction, it is used in roofing, siding & garage doors and acoustic ceilings as corrugated sheets. In chemical and food industries, it is worked into storage tanks and pipes, while in the Oil and Gas industry, it is used for gas lines and fuel tanks. It is also used as truck and trailer roofing in automobiles and for pipe jacketing, as well as cladding in containers and closures in packaging industry. It is used as linings in equipment used for heating and cooling such as radiators, heat exchangers and air conditioners, cooking utensils for home usage, bakery moulds, and for tubes and pipes in offices.

Presence of 1% additional magnesium in its chemical composition, gives Alloy 3004 the upper hand in strength compared to alloy 3003. Hence Alloy 3004 is more expensive compared to alloy 3003 and is the automatic choice in places where material strength is the main criterion.

Most common usage of alloy 3004 is in its rolled form. One can find Alloy 3004 most commonly used in beverage cans (replacing alloy 3003 owing to thinner can need) as it provides solid solution strengthening. It is also used in cooking vessels, chemical equipment, hardware, cabinets, storage tanks and lamp bases.

Alloy 3003 has good finish, excellent formability, welds well, has moderate strength, and resists corrosion. Versatile in its usability and finds application in every sphere of our life. Highly malleable nature coupled with its high plasticity, Alloy 3003 exhibits excellent rust-proof properties and is used in many environments.

An alloy of Aluminium and manganese, Alloy 3004 has good corrosion resistance, workability and possesses more strength than alloy 3003. Most common usage of alloy 3004 is in its rolled form. Presence of 1% additional magnesium gives it the upper hand in strength compared to alloy 3003. Cold working capability of this alloy 3004 is good and is the only means of producing harder tempers of the same.

GET A QUOTE

Share your information

Based in the UAE, Paragon Metal Coating LLC are pioneers in premium-grade aluminum flat-rolled products, aluminum color coating, and high-quality insulation jacketing.

More information

- Career

- Terms and Conditions

- Privacy Policy

Brochure

Copyright 2024 © Paragon | Powered by Paragon